86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

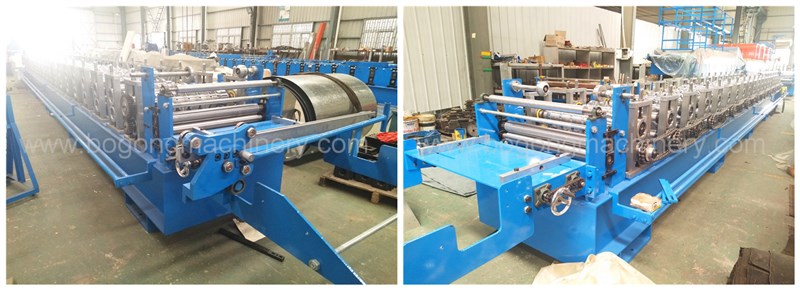

Steel Metal Gusset Plate Roll Forming Machine Decoration Used

- Steel Metal Gusset Plate Roll Forming Machine can be customized designed and manufactured, the gusset plate normally used as house ceiling for decoration, OEM manufactured is acceptable.

- Item No.:YX41-457

Product Orgin:China

Shipping Port:Xiamen, China

Material Thickness: 0.3-0.6mm

Forming Station: 20 Steps

Driving Motor: 7.5KW

Shaft Diameter: 75mm - Contact Us

OEM/ODM design and manufacture are acceptable

Personal custom design is fine also

Product Name: Steel Metal Gusset Plate Roll Forming Machine Decoration Used

Before feeding table, there is entry bench and pre-sheer at steel metal gusset plate roll forming machine's beginning end, see below pictures, the feeding guider on feeding table is adjustable, hand wheel adjusting. This set gusset plate roll forming machine can produce three types of width, D-spacer type change, so we need adjust the material width when we changed to producing anther side of design.

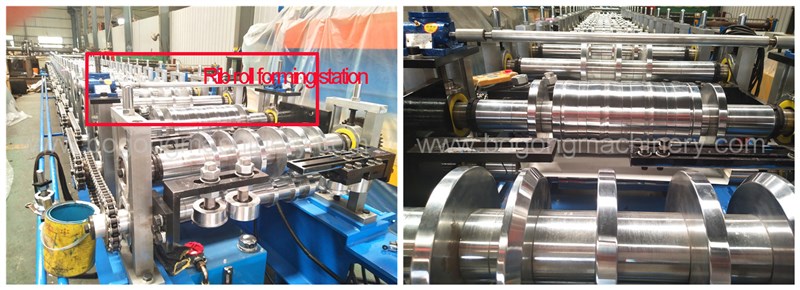

We designed one alone station as option for roll forming ribs. For this Steel Metal Gusset Plate Roll Forming Machine, sometimes, we gusset plate needs ribs, sometimes we needn't ribs, so when need't roll forming ribs on gusset plate, this station rollers can be lifted up, or we adjust down to roll forming ribs. We can compare the gusset plate sample with ribs and without ribs effective on the sample pictures.

Technical Parameters

|

Parameters |

Specification |

|

Voltage |

380V/50HZ/3PH/or customized |

|

Driving Motor |

7.5KW |

|

Forming Steps |

20 steps |

|

Working Speed |

15-20m/min |

|

Thickness for Steel |

0.3-0.6mm (Material:PPGI,GI Steel G550) |

|

Shaft Diameter |

75mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

G45# steel, CNC lathe,polished and chrome plated |

|

PLC Cabinet |

Schneider, Delta |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cut-off System |

Post cutting, no waste cutting |

|

Cutting Blade Material |

Cr12 steel |

|

Machine Frame Material |

Fine welded structural steel; |

|

Roofing Material |

PPGI, GI steel G330-550 |

|

Painted Color |

Blue+Orange Or Customization |

|

Overall Size |

10000*1050*1350mm |

|

Weight |

6500KGS |

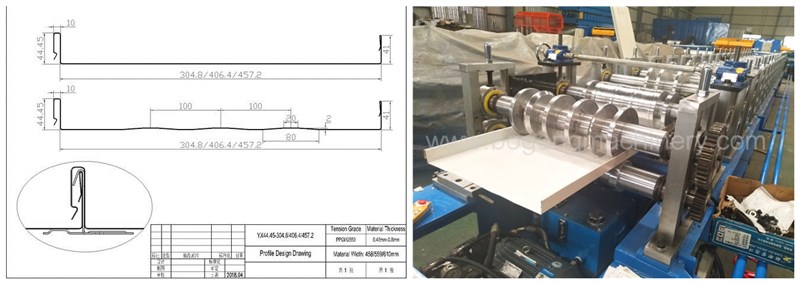

Profile Drawing Drawing

Three feeding width three effective width, changeable design for metal sheet gusset plate roll forming machine profile design, any need, feel free to contact us, we can customize design or OEM for users.

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English