86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

Heavy Duty Storage Shelf System Forming Machine

- The Warehouse Heavy Duty Storage Shelf System Forming Machine line is highly integrated by uncoiling, leveling, forming,cutting off, punching, product rack and other related process. The whole storage shelf system forming machine production line is controlled byPCL program.

- Lead Time:70 Days

Product Orgin:China

Shipping Port:Xiamen, China

Material Thickness: 4mm

Forming Station: 10

Driving Motor: 11KW

Shaft Diameter: 75/95mm

Roller Material: GCr15

Cutting Blade Material: SKD11

Cutting Type: Post Cut

PLC Brand: Simenz Or Custom

Encoder Brand: Encoder - Contact Us

Custom design & manufacture kinds of roll forming machines, such as steel storage shelf, door rail, roller shutter door, high way safety guardrail, roof sheet, floor deck used forming machines.

Name: Heavy Duty Storage Shelf System Forming Machine

Product Description

The Warehouse Heavy Duty Storage Shelf System Forming Machine line is highly integrated by uncoiling, leveling, forming,cutting off, punching, product rack and other related process. The whole storage shelf system forming machine production line is controlled byPCL program.

Machine operators can select a preset program to run the whole line automatically by using touch screen. Whole roll forming machine can be run under automatic control or manual control two working ways. If there is any need to stop the forming machine line, your can press down Emergency stop button and main stop button to check.

Advantages of Storage Shelf Cold Roll Forming Machine

1. Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

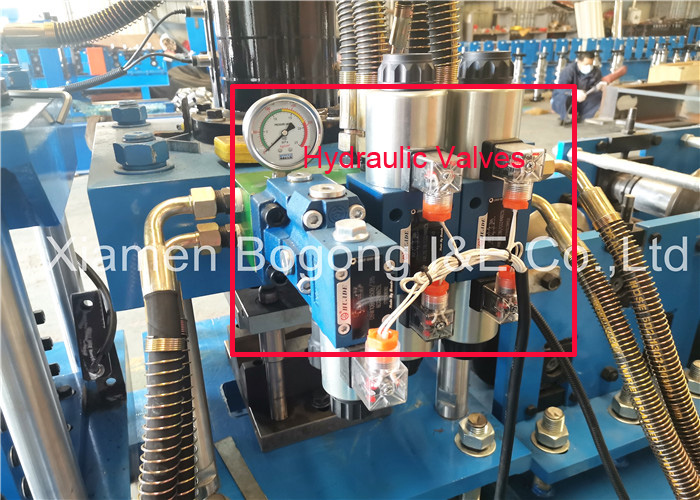

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized

6. Reasonable price: We offer the best price in our industry.

Product Info

|

No.

|

Item | Description |

| 1 | Coil width | According to the final profile |

| 2 | Rolling speed | 0-20m/min(not include cutting and punching time) |

| 3 | Rolling thickness | 1.5-4.0mm |

| 4 | Control system | PLC |

| 5 | De-coiler | 3 TON double head hydraulic de-coiler |

| 6 | Flatten roller | Upper us 3 rollers, down is 4 rollers |

| 7 | Feeding and flatten drive power | 11kw, AC motor |

| 8 | Roller stations | About 10 stations and one correction adjust system |

| 9 | Roller material | Ccr15, chrome plated surface with hardness 58-62 degree ,CNC |

| 10 | Shaft diameter | 40Cr with tempering and hardness |

| 11 | 30Main motor power | 18.5kw, AC motor |

| 12 | Hydraulic station power | 11kw |

| 13 | Servo power | 7.5kw |

| 14 | Cutting mode | Post track cutting |

| 15 | Material of cutting | Cr12Mov |

| 16 | Tolerance | 3m+-1.5mm |

| 17 | Electric source | 380V, 50HZ,3 phase |

| 18 | Way of driving | By gear box |

|

|

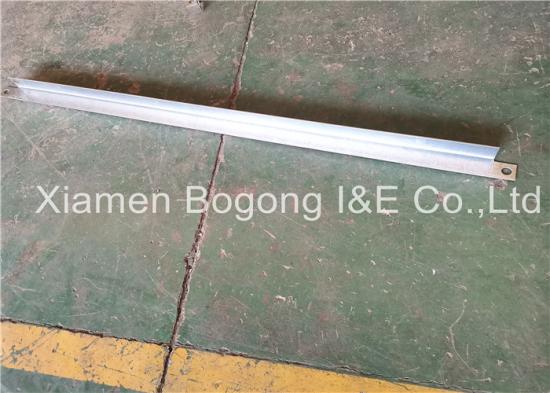

C Track Cutting Roll Forming Machine for sale

|

|

FAQ

1. Q: what is the MOQ?

A: One set

2. Q: What about our after-sale service?

A: we provide technical support on line as well as overseas services by skillful technicians.

3. Q: Are you manufacturer or trading company?

A: We are manufacture and trading company.

4. .Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant pre-sales service.Also we can help you to solve the material(steel

coil)purchase,worker train,international market price.

5. Q:What info you need before you make the proposal?

A:The thickness range which you need or the profile drawings, material information, your special requirements.

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English