86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

High Quality Shutter Door Roll Forming Machine China Factory Suppl

- Xiamen Bogong machinery is a China factory for manufacturer High Quality Shutter Door Roll Forming Machine, it roll forms with 15 stations and whole line is controlled by PLC control system

- Product Orgin:China

Shipping Port:Xiamen, China

Material Thickness: 0.6-1.0mm

Material Width: 125mm

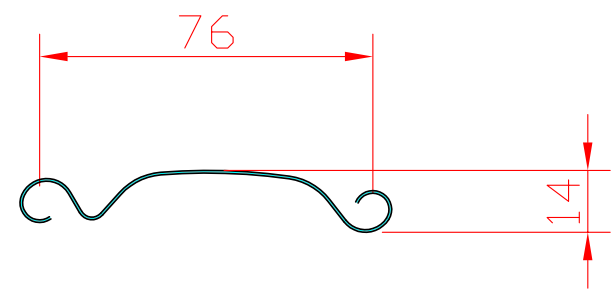

Covered Width: 76

Forming Station: 15

Driving Motor: 4KW

Shaft Diameter: 65mm

Cutting Blade Material: Cr12

Cutting Type: Blanking

Encoder Brand: Omron - Contact Us

Steel metal door, roller shutter door, door guider, door rail roll forming machines are acceptable for customized manufacture

Product name: High Quality Shutter Door Roll Forming Machine China Factory Supply

Profile Design Drawing

This high quality Shutter Door Roll Forming Machine China factory supply is the popular design for shop door, the raw material width is 125mm,the raw material can be pre-painted sheet and galvanized sheet, and suit for 0.6-1.0mm thickness.

Main Machine Details

At the feeding end of high quality Shutter Door Roll Forming Machine China factory supply, there is one group leading roller, it can lead metal material into roll forming machine more smoothly.After leading roller, it is guiding roller, then guiding plate for material head, the guiding plate width can be adjusted by hand wheel, it is convenient for operating.

Whole high quality Shutter Door Roll Forming Machine China factory supply is still not finished, for making sure all the shutter door pieces are straight, we has designed reforming device after roll forming, operator can adjust here if find the shutter door sample is not straight enough.

The most important for shutter door is the overlap, we should produce the shutter door samples all pieces are jointed well, never fall down without manual operation, our machines can do well at this point.

We has plenty of experience to manufacture high quality Shutter Door Roll Forming Machine in China well, and we know how to ensure the important position of whole shutter door samples, so batch and batch shutter door roll forming machines have been shipped to the world market, trust us and contact with us for more professional ideas for your steel doors.

Technical Parameters

|

Parameters |

Specification |

|

Voltage |

220V/60HZ/3PH or customized |

|

Driving Motor |

4 KW |

|

Forming Steps |

15 steps |

|

Working Speed |

10-15m/min |

|

Thickness for Steel |

0.6-1.0mm |

|

Shaft Diameter |

65mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

G45# steel, CNC lathe,polished and chrome plated |

|

PLC Cabinet |

Schneider, Delta |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cut-off System |

Post cutting, no waste cutting |

|

Cutting Blade Material |

Cr12 steel |

|

Machine Frame Material |

Fine welded structural steel; |

|

Raw Material |

GI steel G330-550 |

|

Painted Color |

Blue+Orange Or Customization |

|

Overall Size |

7200*950*1050mm |

|

Weight |

2500KGS |

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English