86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

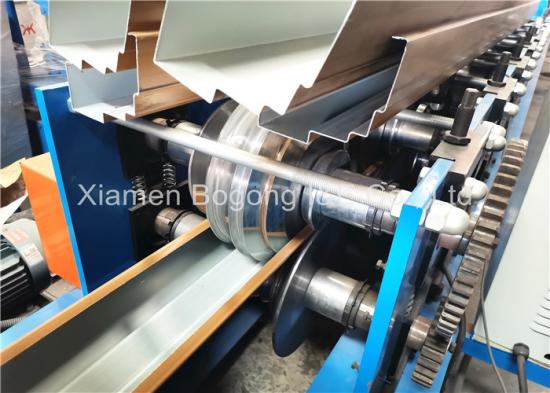

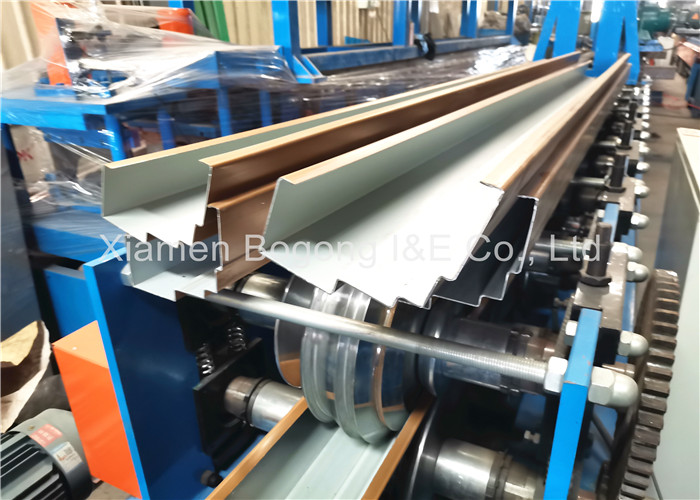

Aluminum Zinc Big Door Frame Roll Forming Machine

- The door frame roll forming machine to produce the big metal door frame, it is vary in size and design depending on load requirements, and styles. When we finish the aluminum zinc big door roll forming machine, we will test the machine and adjust the machine many times to be sure the machine have a perfect status and when customer receive the machine, the machine can be used very easy.

- Lead Time:60-80days

Product Orgin:China

Shipping Port:Xiamen Port

Material Thickness: 1.5-2.5mm

Forming Station: 20 Steps

Driving Motor: 11KW

Shaft Diameter: 75mm

Cutting Blade Material: Cr12

Cutting Type: Waste Material

PLC Brand: Schneider

Encoder Brand: Omron - Contact Us

Customized make kinds of door forming machine, door rail machine and door guider roll forming machine and storage upright post roll forming machine, floor deck machine, roof tile forming machine etc.

Product Name: Aluminum Zinc Big Door Frame Roll Forming Machine

Advantage

The door frame roll forming machine to produce the big metal door frame, it is vary in size and design depending on load requirements, and styles.

When we finish the aluminum zinc big door roll forming machine, we will test the machine and adjust the machine many times to be sure the machine have a perfect status and when customer receive the machine, the machine can be used very easy.

Machine Description

1.Suitable Plate Material: thickness 1.5-2.5mm, Galvanized steel or cold rolled steel

2. Working Speed: 12-15 meters / min

3. Forming Steps: 20 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 75/95mm), thermal refining

6. Driven system: gear box drive

7. Main Power with reducer:11KW

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 5.5KW

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Siemens, Japan English and Chinese Language

13 Touch Screen-- Siemens Japan

14. Encoder--Omron, Japan

15 Electric parts--Schneider

Technical Parameter

A. Manual Decoiler

(1) Max Width: 1250mm

(2) Inner Diameter: 500mm

(3) Outer Diameter: 1200mm

(4) Max Weight Capacity: 5T

B. Big Door Frame Roll Forming Machine

(1) Raw Material: Colored steel or galvanized steel

(2) Material Thickness: 1.5-2mm

(3) Working Speed: 8-12m/min; Adjustable

(4) Rollers: 20 rollers ( based on drawing )

(5) Material for Rollers: GCr15, polished, heated, quenched HRC55-60°

(6) Motor Power: 15KW

(7) Roller Diameter: 76mm

(8) Machine Side Plate Type: Guide Pin Type

(9) Transmission Type: Chain Transmission

(10) Appearance Size: About 10000mm x 1300mm x 1200mm

(11) Total Weight: About 8T

(12) Finished Sheet Product as Stipulation: GB/T 12755-91

C. Hydraulic Cutting

(1) Cutting Type: Hydraulic, automatic cutting

(2) Blade Material: Cr12 with polished, heated, quenched HRC 60-62

(3) Power: 3KW

D. Control System

(1) Electrical Control: PLC Frequency Control System with touch screen

(2) Voltage: 380V/3Ph/50Hz(or as your local standard)

(3) Length Error: ±1mm

E. Output Table

(1) It is simple and used to load finished product

(2) Length: 4m

Working flow

Uncoiling—Feeding&Leveling--Punching Device---Roll forming—Cutting—Products collecting

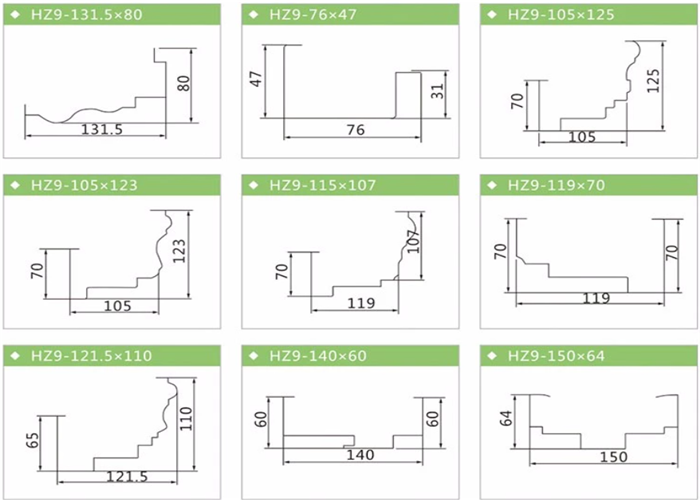

Profile Design Drawing

This steel frame roll forming machine is suit for 1.0-1.5mm material thickness and below is the raw design drawing for reference:

Package

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English