86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

Building Site Working Portable Standing Seam Panel Machine

- Our Building Site Working Portable Standing Seam Panel Machine is portable design, it can be taken to project building site local, Whole roll forming machine has been installed in one 20ft container.

- Product Orgin:China

Shipping Port:Xiamen, China

Material Thickness: 0.3-0.5mm

Forming Station: 14 Steps

Driving Motor: 5.5KW

Shaft Diameter: 75mm - Contact Us

Custom design and manufacture standing seam roof panel roll forming machine, tapered standing seam roof machine/ tapered slitting machine/ arc roof bending machines.

Product Name: Building Site Working Portable Standing Seam Panel Machine

This building site working portable standing seam panel machine is a customized design, whole producing line is layout at 40ft container with glue injection machine, glue pump and PLC control box, also this container will have light lamp, charger plug and other necessary power supply. The buyer can take this line to any project site immediately by truck, then this standing seam panel machine can work soon after connecting power supply.

This building site working portable standing seam panel machine is portable design, it can be taken to project building site local, Whole roll forming machine has been installed in one 40ft container. Before sending finished standing seam roof roll forming machine to user's site, seller can decorate the 40ft container a little, see below picture, we can install electric control box for power supply and also light inside of container.

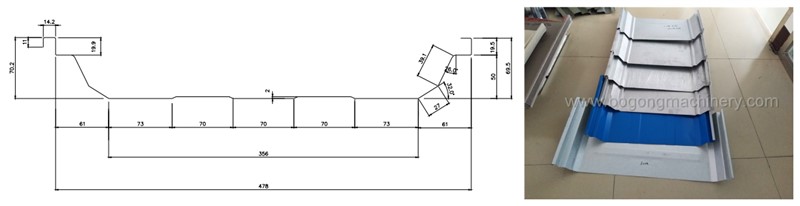

See below profile design drawing for this machine, the feeding width is 600mm, and the reinforce rib can be roll formed or not, we can adjust single station rollers to finish.

Technical Parameters

|

Parameters |

Specification |

|

Voltage |

380V/50HZ/3PH/or customized |

|

Driving Motor |

5.5KW |

|

Forming Steps |

14 steps |

|

Working Speed |

15-20m/min |

|

Thickness for Steel |

0.3-0.5mm (Material:PPGI,GI Steel G550) |

|

Shaft Diameter |

75mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

G45# steel, CNC lathe,polished and chrome plated |

|

PLC Cabinet |

Schneider, Delta |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cut-off System |

Post cutting, no waste cutting |

|

Cutting Blade Material |

Cr12 steel |

|

Machine Frame Material |

Fine welded structural steel; |

|

Roofing Material |

PPGI, GI steel G330-550 |

|

Painted Color |

Blue+Orange Or Customization |

|

Overall Size |

7500*860*1180mm |

|

Weight |

4500KGS |

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English