86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

High Speed Steel Keel Roll Forming Line

- High Speed Steel Keel Roll Forming Line has matched big main driving motor, and whole line is special designed for high speed type roll forming machine, so each part are more stronger enough.

- Product Orgin:China

Shipping Port:Xiamen, China

Material Thickness: 0.4-0.8mm

Forming Station: 11 Stations

Driving Motor: 11Kw

Shaft Diameter: 65mm

Cutting Type: Flying Cut

Encoder Brand: Omron - Contact Us

Custom roll forming machines for light steel hat, metal roof, alumium sheet, floor deck, standing seam roof, metal purlin, roller shutter door and other forming machines

Product name: High Speed Steel Keel Roll Forming Line

Machine Details

Before roll forming the metal strip, there is entry bench feeder and five rollers group straightenning device. Entry bench is good for solve material block problem and pre-straightenning the material strip more flat is more better for roll forming good steel keel shape.

This is High speed steel keel roll forming line, but also a small steel keel roll forming line, whole line matches with portable PLC control box is more convenient for user, it is good for saving layout place.

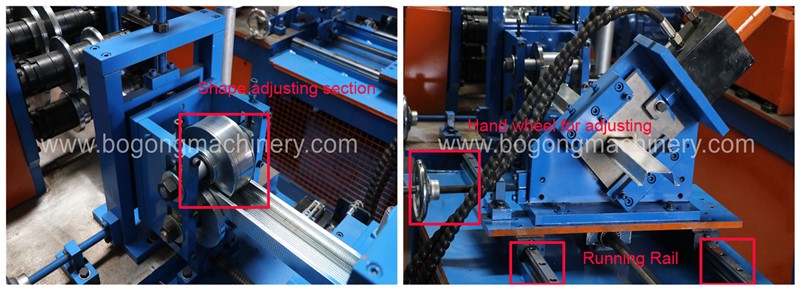

At the cutting end, we have designed shape adjusting section before steel keel will be cut off. See the hand wheel at the side of cutting device, it is for adjusting cutting device whole section left or right alittle for suit for the steel keel position. In order to improving whole Steel Keel Roll Forming Lineproducing speed, this line is flying cutting type, when sample be cut off, the cutting device is running on the rail.

Technical Parameters

|

Parameters |

Specification |

|

Voltage |

380V/50HZ/3PH or customized |

|

Driving Motor |

11KW |

|

Forming Steps |

11 steps |

|

Working Speed |

10-15m/min |

|

Thickness for Steel |

0.4-0.8mm |

|

Shaft Diameter |

65mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

G45# steel, CNC lathe,polished and chrome plated |

|

PLC Cabinet |

Schneider, Delta |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cut-off System |

Post cutting, no waste cutting |

|

Cutting Blade Material |

Cr12 steel |

|

Machine Frame Material |

Fine welded structural steel; |

|

Raw Material |

Galvanized steel |

|

Painted Color |

Blue+Orange Or Customization |

|

Overall Size |

6500*950*1050mm |

|

Weight |

2850KGS |

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English