86 13850031815

[email protected]

- Home About us Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Roof Tile Roll Forming Machine

- Light Keel Roll Forming Machine

- Auxiliary Machine

Roll Forming Machine Engineering Knowledge

How A Metal Roof Will Be Manufactured?

- 2020/09/24

How a Metal Roof Will Be Manufactured?

Once you have time and see new metal roof up on your house, or a house you drive by, will you ever want to know how it was actually made and what goes into the process of manufacturing a metal roof?

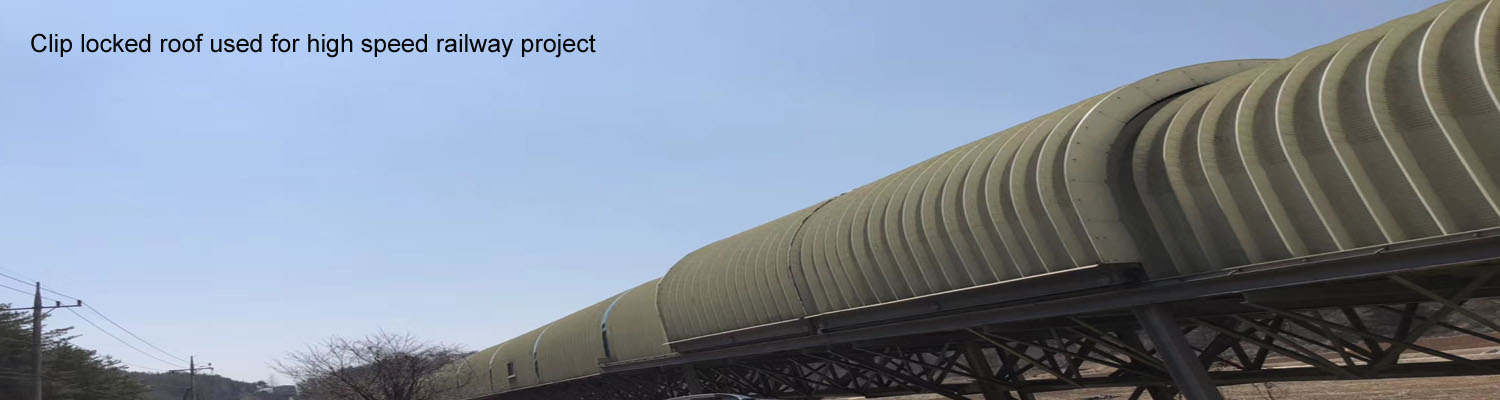

A standing seam roof sheet is the most popular of all metal roofing systems, that is because standing seam roof can be roll-formed by roofing contractors on a job site, or also can be rollformed in a sheet metal shop, to the exact specs provided by the contractor.

Roll-forming Standing Seam Panels

All standing seam metal roofs go through a standing seam metal roofs roll-former --- a machine that turns a metal coil into actual metal roofing panels. The roll former machines can be outfitted with different panel profiles, mechanized or manual shears, computer controller unit, portable or stationary platform / trailer, uncoilers, built-in 10,000 watts generator, and other upgrades, depending on the purposes of its use and how much you want to spend.

The basic process of making standing seam panels involves feeding metal coil into a roll-former. Once inside a roll-former, the metal coil goes through a series of rolls, which make bends and curves. Each successive roll makes more of a bend than a previous one. These rolls are made of hardened stainless steel for increased lifespan and durability. Some can bend a metal as thick as 22 gauge steel.

The rolls make up different standing seam profiles, such as Snap-Lock standing seam, Snap-Lock with a nailing strip (no clips required, when fastening these metal panels to the roof), Mechanical Lock Profile, Crimp panels, and many other exotic profiles.

A panel width can be manually set on each roll-forming machine, but typical widths are 12, 16 and 20” wide panels. Panel width is actually dictated by a metal coil being used. For a 12 "wide panels you need a 16” coil. The “extra” 4 inches are not shaved off inside a roll forming machine ---- they actually go into making the locks on each side of the panel.

The computer control unit takes care of the machine operation / speed, panel length, etc. A smart control unit with automatic shear, can pretty much automate your manufacturing process, by running the coil at specified speed and cutting it at specified length.

Need more knowledge for metal sheet rollformer? Come to send message to us on line or email us soon.

- Contact Us

- No. 788-5D, Jimei North Avenue, Jimei District, Xiamen, China

- 86 13850031815

- 86 13850031815

- [email protected]

- Products

- Custom Roll Forming Machine

- Double Layer Roll Forming Machine

- Purlin Roll Forming Machine

- Roofing Sheet Roll Forming Machine

- Standing Seam Roll Forming Machine

- CNC Bending Machine

- Floor Deck Roll Forming Machine

- Shutter Door Roll Forming Machine

- [email protected]

- 86 13850031815

- 86 13850031815

English

English